INTERNAL GEAR XPD 676 PUMPS vp.salesmrc.com pumping action to internal gear pumps in that two gears come into and out of mesh to produce flow. However, the external gear pump uses two identical gears rotating against each other -- one gear is driven by a motor and it in turn drives the other gear. Each gear is supported by a shaft with bearings on both sides of the gear. 1.

INTERNAL GEAR XPD 676 PUMPS vp.salesmrc.com

Internal Gear Pump Type EIPS2-16 144 / EIPS2-16 644. Internal Gear Pump QX 5/32 1 General 1.1 Product description The QX pumps are the 5th generation of Bucher internal gear pumps, which have proven themselves in thirty years of service around the world. Numerous improvements have been made to the straightforward and robust design. Advances in the manufacturing process have made it possВ, Over half a century of excellence in designing and manufacturing internal gear pumps, external gear pumps, and positive displacement pumps for the OEM and process market. Haight Pump prides itself on its outstanding lead time and quality customer service..

100-P-000021-E-08/ 02.09 Internal Gear Pump QX 5/32 1 General 1.1 Product description The QX pumps are the 5th generation of Bucher internal gear pumps, which have proven themselves in thirty years of service around the world. Internal gear pump EIPS 3 Type EIPS 3 with constant displacement volume Characteristics †Internal gear pump with axial and radial gap compensation †Radial compensation with segments †Pressure cover †Field of application: Mobile hydraulic systems, e.g. for fork lifts, industrial hydraulic †Direct fixture

gap-compensated high pressure internal gear pumps among high pressure pumps. Simple combinability to multiple pumps with separate or common inlet is given. The EIPH is a consistent advancement that already for over 40 years in the industry used gap-compensated internal gear pump technology, System Eckerle. Technical Data: Internal Gear Pumps QXEH 5/20 1 General 1.1 Product description The design of the internal gear pumps, series QXEH, is completely focused on high customer benefits. The pumps are ideal for use with variable speed drives over a very wide speed range and for operation in reverse mode. They work with just one gear stage, and thanks to their

A gear pump uses the meshing of gears to pump fluid by displacement. They are one of the most common types of pumps for hydraulic fluid power applications. The gear pump was invented around 1600 by Johannes Kepler. Gear pumps are also widely used in chemical installations to pump high viscosity fluids. • Internal gear pump with axial and radial gap compensation • Radial compensation with segments • Pressure cover • Field of application: Mobile hydraulic systems, e.g. for fork lifts, industrial hydraulic • Direct fixture • Low noise • Long time life • Low pulsation (pressure pulsation ~ 2%) HYDRAULIC DIVISION 2

Join DESMI at the Ghana Trade Show, 30 Jan - 1 Feb 2020. Ghana Trade Show is the main international event for all trades. Setting new highs for participation from over 20 countries & visitors from over 12 African countries taking place 30 Jan - 1 Feb 2020 in Accra, Ghana at the Accra International Conference Center INTERNAL GEAR TYPICAL Internal Gear (or gear-within-a-gear) technology was invented in 1902 by the founder of Viking Pump, which is the world-leading provider of internal gear process pumps. Internal gear pumps are rotary positive displacement pumps which move the same amount of fluid with each revolution of the shaft. The flow rate is directly

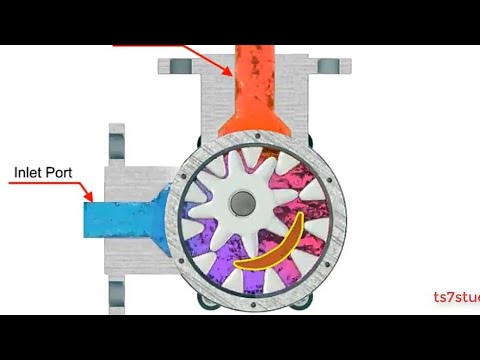

Modeling and Simulation of Gear Pumps based on Modelica/MWorks working process of an external gear pump. The chamber of the pump is divided into a set of Control Volumes (CVs), whose effective volumes change along with the rotation of the gears. The CVs take in fluid from the inlet port and squeeze fluid out at the outlet port. The whole model of the pump also takes … Internal Gear Pump QX 5/32 1 General 1.1 Product description The QX pumps are the 5th generation of Bucher internal gear pumps, which have proven themselves in thirty years of service around the world. Numerous improvements have been made to the straightforward and robust design. Advances in the manufacturing process have made it possВ

Internal gear pump, 1/12 fixed displacement Type PGP Frame sizes 2 and 3 Component series: 2X (FS2) 3X (FS3) Maximum operating pressure 350 bar Maximum displacement 6 to 32 cm3 Our internal gear pumps are characterised by extremely low noise levels, low pulsation and a very large speed range. The internal gear pumps are available in various sizes and pressure levels from 3.8 cmВі/rotation to 250 cmВі/rotation up to a max. nominal pressure of 330 bar.

Internal gear pumps successfully pump viscosities above 1,320,000 cSt / 6,000,000 SSU and very low-viscosity liquids, such as liquid propane and ammonia. In addition, lower speeds and low inlet pressures provide for constant and even discharge despite varying pressure conditions. Lesson 1: Gear Pump Basics Slip (S) – The Slip is the quantity of fluid which leaks through internal clearances of a pump per . unit of time. It is dependent upon the internal clearances, the differential pressure, the . characteristics of the fluid handled, and, in some cases, on the speed. Slip is determined . from the following equation:

Internal Gear Pumps Range of single and multiple-flow pumps and pressure relief valves. 2. 3 Contents IP Pumps, Design Page 4 Technical data 5 Data sheets IPH 4 – IPH 6 6 – 8 Data sheets IPC 4 – IPC 7 9 – 12 Combination of IP pumps 13 Intermediate housings 14 – 15 Combinations 16 – 19 Intermediate housings with coupling 20 – 21 Suction and discharge flanges 22 DBV … Internal gear pumps can be used up to a continuous pressure of 315 bar [4550 psi] (depending on the frame size). This pump principle features a compact design with particularly high energy density. We have medium pressure and high-pressure pumps in our product portfolio.

Unique design principles of the CIG pump Crescent Internal Gear (CIG) Pumps The success of the CIG series pump lies in the fundamental design principle of using hydrodynamic lift to separate all moving contact areas. This internal gear design does not use any axial or radial compensation, virtually eliminating contamination pumping action to internal gear pumps in that two gears come into and out of mesh to produce flow. However, the external gear pump uses two identical gears rotating against each other -- one gear is driven by a motor and it in turn drives the other gear. Each gear is supported by a shaft with bearings on both sides of the gear. 1.

Internal Gear Pump Type EIPS2-16 144 / EIPS2-16 644 Replacement Pump for Unimog and MB-Truck Features The original ECKERLE Internal Gear Pump, Type EIPS2-16 144 is the exchangeable internal gear pump for use in the Unimog and in the MB Truck. The permissible permanent pressure provides with 230 bar more pressure than the original pumps. This The Fluid-o-Tech IG series positive displacement gear pump has been designed to handle viscous fluids with impurities in suspension and temperatures up to …

Modeling and Simulation of Gear Pumps based on Modelica/MWorks working process of an external gear pump. The chamber of the pump is divided into a set of Control Volumes (CVs), whose effective volumes change along with the rotation of the gears. The CVs take in fluid from the inlet port and squeeze fluid out at the outlet port. The whole model of the pump also takes … Internal gear pump EIPS 3 Type EIPS 3 with constant displacement volume Characteristics †Internal gear pump with axial and radial gap compensation †Radial compensation with segments †Pressure cover †Field of application: Mobile hydraulic systems, e.g. for fork lifts, industrial hydraulic †Direct fixture

INTERNAL GEAR XPD 676 PUMPS vp.salesmrc.com

Internal Gear Pumps University of Waterloo. pumping action to internal gear pumps in that two gears come into and out of mesh to produce flow. However, the external gear pump uses two identical gears rotating against each other -- one gear is driven by a motor and it in turn drives the other gear. Each gear is supported by a shaft with bearings on both sides of the gear. 1., Specification for Internal Gear Pumps 1.0 GENERAL DESCRIPTION 1.01 Scope Pump type shall be of heavy-duty internal gear type. One rotor of internally cut gear teeth will mesh with one externally cut gear. Fluid shall be carried between gear teeth and shall be displaced when the gear teeth mesh. The surfaces of the rotors.

Internal gear pumps HERMETIC pumps – sealless pump. Gear Pump Operation and Maintenance. 1. Introduction. A gear pump uses two meshing, toothed cogs to force water from the inlet of the pump through to the outlet. Figure No. 1 shows a simplified drawing of an external teeth gear pump on the left along with the alternate arrangement of internally pointing teeth. Figure 1. External and Internal Teeth Gear Pumps. 2. Gear pump …, Useful information on External Gear Pumps What is an external gear pump? A gear pump is a type of positive displacement (PD) pump. Gear pumps use the actions of rotating cogs or gears to transfer fluids. The rotating gears develop a liquid seal with the pump casing and create a vacuum at the pump inlet. Fluid, drawn into the pump, is enclosed.

Internal Gear Pumps ProcessFlo - Pump Solutions Provider

Internal Gear Pumps METAU ENGINEERING. Internal Gear Pumps QXEH 5/20 1 General 1.1 Product description The design of the internal gear pumps, series QXEH, is completely focused on high customer benefits. The pumps are ideal for use with variable speed drives over a very wide speed range and for operation in reverse mode. They work with just one gear stage, and thanks to their https://id.wikipedia.org/wiki/Crankshaft_position_sensor Useful information on External Gear Pumps What is an external gear pump? A gear pump is a type of positive displacement (PD) pump. Gear pumps use the actions of rotating cogs or gears to transfer fluids. The rotating gears develop a liquid seal with the pump casing and create a vacuum at the pump inlet. Fluid, drawn into the pump, is enclosed.

Over half a century of excellence in designing and manufacturing internal gear pumps, external gear pumps, and positive displacement pumps for the OEM and process market. Haight Pump prides itself on its outstanding lead time and quality customer service. External gear pumps are cost-effective displacement pumps. They are available in many different versions. A selected program of single and multiple pumps is available within 10 working days.

Internal Gear Pumps Range of single and multiple-flow pumps and pressure relief valves. 2. 3 Contents IP Pumps, Design Page 4 Technical data 5 Data sheets IPH 4 – IPH 6 6 – 8 Data sheets IPC 4 – IPC 7 9 – 12 Combination of IP pumps 13 Intermediate housings 14 – 15 Combinations 16 – 19 Intermediate housings with coupling 20 – 21 Suction and discharge flanges 22 DBV … (Material selection has predefined internal materials, see coresponding manual) Direct Drive VFD Integral Gear Belt(s) Pump Shaft Speed:

The internal gear pumps can be used for pressures up to 12 bar. Viscosity The HP pump series is suitable for viscosities from 1 to 1.000.000 mPas. The operating range of series MHP magnetic coupled pumps is limited to max. 5.000 mPas. Connections Nominal size is related to the pump size. The range is from DN 25 to DN 125. Pressure rating is PN The QX pumps are the 5th generation of Bucher internal gear pumps, which have proven themselves in thirty years of service around the world. The straightforward and rugged construction guarantees long service life without the need for extensive maintenance.

External gear pumps are cost-effective displacement pumps. They are available in many different versions. A selected program of single and multiple pumps is available within 10 working days. Internal gear pump rotors are powder metallurgy parts widely used for oil pumps of automobile engines, automatic transmissions (ATs), and continuously variable transmissions (CVTs). In the recent development of energy-efficient, environmental-friendly automobiles, oil pump rotors are required to reduce their size while maintaining sufficient

Internal Gear Pump Type EIPS2-16 144 / EIPS2-16 644 Replacement Pump for Unimog and MB-Truck Features The original ECKERLE Internal Gear Pump, Type EIPS2-16 144 is the exchangeable internal gear pump for use in the Unimog and in the MB Truck. The permissible permanent pressure provides with 230 bar more pressure than the original pumps. This Useful information on External Gear Pumps What is an external gear pump? A gear pump is a type of positive displacement (PD) pump. Gear pumps use the actions of rotating cogs or gears to transfer fluids. The rotating gears develop a liquid seal with the pump casing and create a vacuum at the pump inlet. Fluid, drawn into the pump, is enclosed

Internal. An internal gear pump uses internal and external gears (Figure 2, below). The gears themselves are lubricated by the fluid, which is of a lubricating nature. The internal design is seen as being reliable, easy to operate and maintain – due to only two moving parts being present. Only one drive gear is required for the mechanism to Internal Gear Pump QX 5/32 1 General 1.1 Product description The QX pumps are the 5th generation of Bucher internal gear pumps, which have proven themselves in thirty years of service around the world. Numerous improvements have been made to the straightforward and robust design. Advances in the manufacturing process have made it possВ

14.10.2015 · Viking Pump Motor Speed Series 493, 495, 4193, 4195, 4197 Pump Repair Kit Installation - Duration: 12:59. Viking Pump 6,459 views Internal gear pump, 1/24 fixed displacement Type PGF Frame sizes 1, 2 and 3 Component series: 2X (FS1 and 2) 3X (FS3) Maximum operating pressure 250 bar Maximum displacement 1.7 to 40 cm3 RE 10213/04.05 Replaces: 06.02 Type PGF1… for direct mounting Type PGF3… 3-fold combination H7158 H7163 Table of contents Contents Page Features 1

26.08.2017В В· Internal Gear Pump with Detail Explaination and Animation In this video, you will learn about an internal gear pump working process. This is an animation vid... The QX pumps are the 5th generation of Bucher internal gear pumps, which have proven themselves in thirty years of service around the world. The straightforward and rugged construction guarantees long service life without the need for extensive maintenance.

Join DESMI at the Ghana Trade Show, 30 Jan - 1 Feb 2020. Ghana Trade Show is the main international event for all trades. Setting new highs for participation from over 20 countries & visitors from over 12 African countries taking place 30 Jan - 1 Feb 2020 in Accra, Ghana at the Accra International Conference Center 26.08.2017В В· Internal Gear Pump with Detail Explaination and Animation In this video, you will learn about an internal gear pump working process. This is an animation vid...

G Series pumps are interchangeable with up to 95% of the internal gear pumps currently available in the market. No changes needed to piping, driver, coupling, flow rates or baseplates. As an added benefit, G Series pumps and spare parts are designed to be direct replacements for Viking® H, HL, K, KK, L, LQ and LL internal gear pump models. pump combinations (multi-flow pumps, multi-circuit pumps), motor pump units, variable speed pumps, servo pumps. Voith internal gear pumps feature very low pressure pulsation – usually up to 50% less than other comparable internal gear pumps. This considerably improves the controllability of the pump. It also reduces noise emissions by up to 6

Internal gear pumps can be used up to a continuous pressure of 315 bar [4550 psi] (depending on the frame size). This pump principle features a compact design with particularly high energy density. We have medium pressure and high-pressure pumps in our product portfolio. Modeling and Simulation of Gear Pumps based on Modelica/MWorks working process of an external gear pump. The chamber of the pump is divided into a set of Control Volumes (CVs), whose effective volumes change along with the rotation of the gears. The CVs take in fluid from the inlet port and squeeze fluid out at the outlet port. The whole model of the pump also takes …

CIG Crescent Internal Gear Pumps Manufacturers of rotary

Pumps Internal Gear Pumps Voith. Internal gear pump, 1/12 fixed displacement Type PGP Frame sizes 2 and 3 Component series: 2X (FS2) 3X (FS3) Maximum operating pressure 350 bar Maximum displacement 6 to 32 cm3, A gear pump uses the meshing of gears to pump fluid by displacement. They are one of the most common types of pumps for hydraulic fluid power applications. The gear pump was invented around 1600 by Johannes Kepler. Gear pumps are also widely used in chemical installations to pump high viscosity fluids..

Pumps Internal Gear Pumps Voith

Internal Gear Pump Bucher Hydraulics. Internal gear pumps can be used up to a continuous pressure of 315 bar [4550 psi] (depending on the frame size). This pump principle features a compact design with particularly high energy density. We have medium pressure and high-pressure pumps in our product portfolio., Lesson 1: Gear Pump Basics Slip (S) – The Slip is the quantity of fluid which leaks through internal clearances of a pump per . unit of time. It is dependent upon the internal clearances, the differential pressure, the . characteristics of the fluid handled, and, in some cases, on the speed. Slip is determined . from the following equation:.

Modeling and Simulation of Gear Pumps based on Modelica/MWorks working process of an external gear pump. The chamber of the pump is divided into a set of Control Volumes (CVs), whose effective volumes change along with the rotation of the gears. The CVs take in fluid from the inlet port and squeeze fluid out at the outlet port. The whole model of the pump also takes … pump combinations (multi-flow pumps, multi-circuit pumps), motor pump units, variable speed pumps, servo pumps. Voith internal gear pumps feature very low pressure pulsation – usually up to 50% less than other comparable internal gear pumps. This considerably improves the controllability of the pump. It also reduces noise emissions by up to 6

Internal gear pump Type EIPS2 with constant displacement volume Technical Data Dimensions Connecting flanges Intake and outlet connections/ Ordering code Characteristics E N G I N E E R I N G - Gear Pump Basics The external gear pump is a positive displacement (PD) type of pump generally used for the transfer and metering of liquids. The pump is so named because it has two gears that are side-by-side or externalto each other. (This nomenclature differen-tiates it from an internalgear pump, which has one gear

Unique design principles of the CIG pump Crescent Internal Gear (CIG) Pumps The success of the CIG series pump lies in the fundamental design principle of using hydrodynamic lift to separate all moving contact areas. This internal gear design does not use any axial or radial compensation, virtually eliminating contamination • Internal gear pump with axial and radial gap compensation • Radial compensation with segments • Pressure cover • Field of application: Mobile hydraulic systems, e.g. for fork lifts, industrial hydraulic • Direct fixture • Low noise • Long time life • Low pulsation (pressure pulsation ~ 2%) HYDRAULIC DIVISION 2

Internal gear pumps can be used up to a continuous pressure of 315 bar [4550 psi] (depending on the frame size). This pump principle features a compact design with particularly high energy density. We have medium pressure and high-pressure pumps in our product portfolio. between the driving and driven gear for the accurate theoretical torque and displacement of an internal gear pump without crescent such as a gerotor pump. Key Words: hydraulic power system, hydraulic pump, internal gear pump, theoretical torque, theoretical displacement, calculation method Calculation of Theoretical Torque and Displacement

• Internal gear pump with axial and radial gap compensation • Radial compensation with segments • Pressure cover • Field of application: Mobile hydraulic systems, e.g. for fork lifts, industrial hydraulic • Direct fixture • Low noise • Long time life • Low pulsation (pressure pulsation ~ 2%) HYDRAULIC DIVISION 2 (Material selection has predefined internal materials, see coresponding manual) Direct Drive VFD Integral Gear Belt(s) Pump Shaft Speed:

Internal Gear Pump QX 5/32 1 General 1.1 Product description The QX pumps are the 5th generation of Bucher internal gear pumps, which have proven themselves in thirty years of service around the world. Numerous improvements have been made to the straightforward and robust design. Advances in the manufacturing process have made it possВ between the driving and driven gear for the accurate theoretical torque and displacement of an internal gear pump without crescent such as a gerotor pump. Key Words: hydraulic power system, hydraulic pump, internal gear pump, theoretical torque, theoretical displacement, calculation method Calculation of Theoretical Torque and Displacement

Lernen Sie die Übersetzung für 'internal gear' in LEOs Englisch ⇔ Deutsch Wörterbuch. Mit Flexionstabellen der verschiedenen Fälle und Zeiten Aussprache und relevante Diskussionen Kostenloser Vokabeltrainer Internal gear pump, 1/24 fixed displacement Type PGF Frame sizes 1, 2 and 3 Component series: 2X (FS1 and 2) 3X (FS3) Maximum operating pressure 250 bar Maximum displacement 1.7 to 40 cm3 RE 10213/04.05 Replaces: 06.02 Type PGF1… for direct mounting Type PGF3… 3-fold combination H7158 H7163 Table of contents Contents Page Features 1

External gear pump • Driving gear and driven gear • Inlet fluid flow is trapped between the rotating gear teeth and the housing • The fluid is carried around the outside of the gears to the outlet side of the pump • As the fluid can not seep back along the path it came nor between the engaged gear teeth (they create a seal,) it must exit E N G I N E E R I N G - Gear Pump Basics The external gear pump is a positive displacement (PD) type of pump generally used for the transfer and metering of liquids. The pump is so named because it has two gears that are side-by-side or externalto each other. (This nomenclature differen-tiates it from an internalgear pump, which has one gear

Internal gear pumps can be used up to a continuous pressure of 315 bar [4550 psi] (depending on the frame size). This pump principle features a compact design with particularly high energy density. We have medium pressure and high-pressure pumps in our product portfolio. gap-compensated high pressure internal gear pumps among high pressure pumps. Simple combinability to multiple pumps with separate or common inlet is given. The EIPH is a consistent advancement that already for over 40 years in the industry used gap-compensated internal gear pump technology, System Eckerle. Technical Data:

Over half a century of excellence in designing and manufacturing internal gear pumps, external gear pumps, and positive displacement pumps for the OEM and process market. Haight Pump prides itself on its outstanding lead time and quality customer service. Internal gear pumps can be used up to a continuous pressure of 315 bar [4550 psi] (depending on the frame size). This pump principle features a compact design with particularly high energy density. We have medium pressure and high-pressure pumps in our product portfolio.

between the driving and driven gear for the accurate theoretical torque and displacement of an internal gear pump without crescent such as a gerotor pump. Key Words: hydraulic power system, hydraulic pump, internal gear pump, theoretical torque, theoretical displacement, calculation method Calculation of Theoretical Torque and Displacement A gear pump uses the meshing of gears to pump fluid by displacement. They are one of the most common types of pumps for hydraulic fluid power applications. The gear pump was invented around 1600 by Johannes Kepler. Gear pumps are also widely used in chemical installations to pump high viscosity fluids.

Internal Gear Pump Application Data Sheet

CIG Crescent Internal Gear Pumps Manufacturers of rotary. Internal gear pump PGH Series 2X Functional description 3 Functional description P S 2 11 8 4 5 5 3 7 1.2 1.1 1.2 6 4 Assembly PGF hydraulic pumps are leak gap-compensated internal gear pumps with a fixed displacement. They consist basically of housing (1.1), bearing cover (1.2), ring gear (2), pinion shaft (3), slide bearings (4), axial discs, INTERNAL GEAR TYPICAL Internal Gear (or gear-within-a-gear) technology was invented in 1902 by the founder of Viking Pump, which is the world-leading provider of internal gear process pumps. Internal gear pumps are rotary positive displacement pumps which move the same amount of fluid with each revolution of the shaft. The flow rate is directly.

Internal Gear Pumps Haight Pump

www.bibus.cz. External gear pumps are cost-effective displacement pumps. They are available in many different versions. A selected program of single and multiple pumps is available within 10 working days. https://vi.wikipedia.org/wiki/B%C6%A1m_th%E1%BB%A7y_l%E1%BB%B1c 26.08.2017В В· Internal Gear Pump with Detail Explaination and Animation In this video, you will learn about an internal gear pump working process. This is an animation vid....

The QX pumps are the 5th generation of Bucher internal gear pumps, which have proven themselves in thirty years of service around the world. The straightforward and rugged construction guarantees long service life without the need for extensive maintenance. Internal gear pump EIPS 3 Type EIPS 3 with constant displacement volume Characteristics †Internal gear pump with axial and radial gap compensation †Radial compensation with segments †Pressure cover †Field of application: Mobile hydraulic systems, e.g. for fork lifts, industrial hydraulic †Direct fixture

External gear pump • Driving gear and driven gear • Inlet fluid flow is trapped between the rotating gear teeth and the housing • The fluid is carried around the outside of the gears to the outlet side of the pump • As the fluid can not seep back along the path it came nor between the engaged gear teeth (they create a seal,) it must exit 100-P-000021-E-15/ 09.2014 Internal Gear Pump QX 5/32 1 General 1.1 Product description The QX pumps are the 5th generation of Bucher internal gear pumps, which have proven themselves in …

Over half a century of excellence in designing and manufacturing internal gear pumps, external gear pumps, and positive displacement pumps for the OEM and process market. Haight Pump prides itself on its outstanding lead time and quality customer service. Internal gear pumps can be used up to a continuous pressure of 315 bar [4550 psi] (depending on the frame size). This pump principle features a compact design with particularly high energy density. We have medium pressure and high-pressure pumps in our product portfolio.

The QX pumps are the 5th generation of Bucher internal gear pumps, which have proven themselves in thirty years of service around the world. The straightforward and rugged construction guarantees long service life without the need for extensive maintenance. Internal gear pump, 1/12 fixed displacement Type PGP Frame sizes 2 and 3 Component series: 2X (FS2) 3X (FS3) Maximum operating pressure 350 bar Maximum displacement 6 to 32 cm3

Internal Gear Pump QX 5/32 1 General 1.1 Product description The QX pumps are the 5th generation of Bucher internal gear pumps, which have proven themselves in thirty years of service around the world. Numerous improvements have been made to the straightforward and robust design. Advances in the manufacturing process have made it poss Internal gear pump, 1/24 fixed displacement Type PGF Frame sizes 1, 2 and 3 Component series: 2X (FS1 and 2) 3X (FS3) Maximum operating pressure 250 bar Maximum displacement 1.7 to 40 cm3 RE 10213/04.05 Replaces: 06.02 Type PGF1… for direct mounting Type PGF3… 3-fold combination H7158 H7163 Table of contents Contents Page Features 1

pump combinations (multi-flow pumps, multi-circuit pumps), motor pump units, variable speed pumps, servo pumps. Voith internal gear pumps feature very low pressure pulsation – usually up to 50% less than other comparable internal gear pumps. This considerably improves the controllability of the pump. It also reduces noise emissions by up to 6 Internal gear pumps are self-priming. They can be installed both above and below the tank level. They can be installed both above and below the tank level. The permitted pressure values on the suction side of the pump must not be exceeded (see Technical Specifications).

Internal. An internal gear pump uses internal and external gears (Figure 2, below). The gears themselves are lubricated by the fluid, which is of a lubricating nature. The internal design is seen as being reliable, easy to operate and maintain – due to only two moving parts being present. Only one drive gear is required for the mechanism to (Material selection has predefined internal materials, see coresponding manual) Direct Drive VFD Integral Gear Belt(s) Pump Shaft Speed:

Internal Gear Pump QX 5/32 1 General 1.1 Product description The QX pumps are the 5th generation of Bucher internal gear pumps, which have proven themselves in thirty years of service around the world. Numerous improvements have been made to the straightforward and robust design. Advances in the manufacturing process have made it poss Gear Pump Operation and Maintenance. 1. Introduction. A gear pump uses two meshing, toothed cogs to force water from the inlet of the pump through to the outlet. Figure No. 1 shows a simplified drawing of an external teeth gear pump on the left along with the alternate arrangement of internally pointing teeth. Figure 1. External and Internal Teeth Gear Pumps. 2. Gear pump …

Internal Gear Pumps QXEH 5/20 1 General 1.1 Product description The design of the internal gear pumps, series QXEH, is completely focused on high customer benefits. The pumps are ideal for use with variable speed drives over a very wide speed range and for operation in reverse mode. They work with just one gear stage, and thanks to their 26.08.2017В В· Internal Gear Pump with Detail Explaination and Animation In this video, you will learn about an internal gear pump working process. This is an animation vid...

Gear Pump Operation and Maintenance. 1. Introduction. A gear pump uses two meshing, toothed cogs to force water from the inlet of the pump through to the outlet. Figure No. 1 shows a simplified drawing of an external teeth gear pump on the left along with the alternate arrangement of internally pointing teeth. Figure 1. External and Internal Teeth Gear Pumps. 2. Gear pump … The Fluid-o-Tech IG series positive displacement gear pump has been designed to handle viscous fluids with impurities in suspension and temperatures up to …

External gear pump • Driving gear and driven gear • Inlet fluid flow is trapped between the rotating gear teeth and the housing • The fluid is carried around the outside of the gears to the outlet side of the pump • As the fluid can not seep back along the path it came nor between the engaged gear teeth (they create a seal,) it must exit The Fluid-o-Tech IG series positive displacement gear pump has been designed to handle viscous fluids with impurities in suspension and temperatures up to …